Table of Contents

11 Cutting-Edge Construction Techniques for Today’s Buildings

Digital and Data-Driven Innovations

Build Smarter with Claris Design•Build!

Key Takeaways

✔ Modern construction is shifting toward digital-first planning and visualization to reduce errors before building starts.

✔ Off-site and automated production (like modular systems and robotics) is cutting timelines and improving consistency.

✔ New methods aim to use materials more efficiently, lowering waste and overall project cost.

✔ Sustainability is now built into technique choices, pushing lower-carbon, energy-smart designs as the default.

✔ Real-time data tools are making sites safer, more predictable, and easier to manage day to day.

When it comes to construction, builders and developers need to stay up-to-date to work smarter, spend less, and be more eco-friendly. That's where modern methods of construction (MMC) come in. These new techniques are changing the game by using the latest technology and materials to build faster, better-quality buildings.

Here are 13 exciting construction techniques that are making a big difference in how modern buildings are made.

13 Cutting-Edge Construction Techniques for Today’s Buildings

Advanced Techniques

1. 3D Printing

3D printing uses a digital model to create structures by placing materials such as concrete in thin layers, often directly on-site. This allows builders to form complex shapes without extensive molds or formwork. It can shorten construction timelines, reduce labor needs, and limit material waste through precise deposition. The technique is increasingly used for housing, structural elements, and customized architectural components.

2. Modular and Prefabricated Construction

Modular and prefabricated construction moves major building work into factories, where walls, floors, or full room units are produced under controlled conditions. These parts are then transported to the site and assembled quickly, like a high-precision kit. This approach improves quality consistency, minimizes weather delays, and speeds up project completion. It also supports cost predictability and easier scaling for repeatable building types.

3. Robotics and Automation

Robotics and automation bring machines into construction to take on repetitive, heavy, or high-risk work such as bricklaying, welding, and excavation, improving precision, speed, and safety throughout a project. This shift is accelerating worldwide, since global demand for construction robots is expected to rise as more firms push automation initiatives and invest more funding into modernizing how they build.

Digital and Data-Driven Innovations

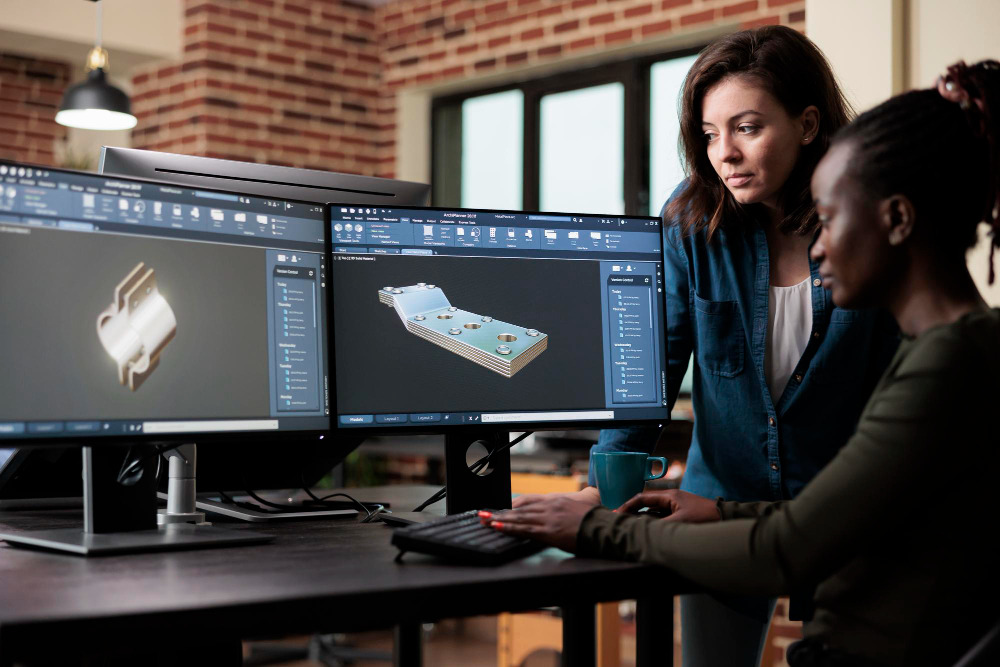

4. Building Information Modeling (BIM)

Building Information Modeling creates a detailed 3D digital representation of a building that includes geometry plus data on materials, systems, costs, and schedules. It acts as a shared workspace so architects, engineers, and contractors coordinate from one reliable model. This helps detect design clashes early and prevents costly rework on-site. BIM also supports lifecycle management by carrying useful information into operations and maintenance.

5. Augmented Reality (AR)

According to FinancesOnline, technology leaders expect AR to surpass VR within the next 3 to 5 years, presenting a wide range of opportunities. When combined with Building Information Modeling (BIM), AR allows construction professionals to interact with a fully-rendered 3D model of a building before the construction even begins. This construction technique enables a more accurate and detailed planning phase. Additionally, it also aids with the efficient allocation of resources to avoid wastage.

6. Artificial Intelligence (AI)

Artificial Intelligence analyzes large amounts of project and site data to improve planning, prediction, and decision-making. It can forecast schedule delays, cost overruns, and safety risks by spotting patterns humans might miss. AI also supports design optimization and smarter resource allocation to reduce waste. As adoption grows, it increasingly functions as a real-time decision-support layer across construction phases.

Innovative Materials

7. Engineered Timber

Engineered timber is made by bonding layers of wood into strong structural products such as CLT or glulam. These materials provide high strength while being lighter than steel or concrete, making transport and installation easier. They also have a lower carbon footprint, since wood stores carbon and requires less energy to process. Engineered timber supports faster construction and modern architectural flexibility.

8. Recycled Concrete

Recycled concrete uses crushed concrete from demolished structures as aggregate for new mixes. This reduces landfill waste and lowers demand for fresh raw materials like gravel and sand. When properly processed, it can still meet structural performance requirements for many applications. It also helps cut embodied carbon compared with fully new concrete production.

9. Hempcrete

Hempcrete is a bio-composite made from hemp shiv mixed with a lime-based binder, forming a lightweight insulating material. It is not typically load-bearing, but it works well as wall infill and insulation. Hempcrete offers good thermal regulation, moisture control, and fire resistance. Because hemp grows quickly and absorbs CO₂, it supports low-impact building goals.

10. Sugarcrete

Sugarcrete is produced from sugarcane byproducts combined with binders to form blocks or panels. It aims to reuse agricultural waste while creating lightweight, insulating building materials. The result can reduce embodied energy compared with traditional bricks. Although still emerging, it shows promise for sustainable and affordable construction.

11. Self-Healing Concrete

Self-healing concrete contains additives such as bacteria, polymers, or mineral capsules that activate when cracks appear. These agents seal gaps automatically, reducing water infiltration and slowing reinforcement corrosion. This improves durability and extends structural lifespan. It is especially useful where repairs are costly or hard to access, like bridges and high-rise elements.

12. Graphene

Graphene is an ultra-strong, lightweight carbon nanomaterial that can be added to concrete or coatings in small amounts. It enhances compressive strength, reduces permeability, and improves long-term durability. This can allow structures to use less material while performing better. Graphene-based mixes are still scaling up but are gaining attention for high-performance builds.

13. Bendable Concrete (ECC)

Bendable concrete, also known as engineered cementitious composite (ECC), is designed to flex under stress instead of cracking suddenly. It achieves this through fiber reinforcement and an optimized mix design that spreads small microcracks rather than one large break. This makes it far more resilient in earthquakes and heavy-load conditions. ECC can reduce maintenance needs by limiting major cracking over time.

Frequently Asked Questions

Can you use these construction techniques in any climate?

Current construction techniques are adaptable to various climates. Techniques like ICF are great for cold areas, while precast concrete foundations are ideal for extreme weather regions. Choosing the right method for your climate ensures your building is efficient and durable.

How do these construction techniques impact the overall cost of a building project?

Modern construction techniques can lower project costs in the long run. While some methods might have higher upfront costs, they often lead to savings through quicker construction times, less labor, and reduced waste. Over time, investing in these techniques pays off by speeding up the build process and minimizing errors.

Are modern construction techniques better for the environment?

Many of these techniques focus on sustainability, using eco-friendly materials, and reducing waste. For example, timber framing uses renewable resources, and methods like ICF improve energy efficiency, leading to a smaller carbon footprint for buildings. These environmentally conscious choices help create greener buildings.

How is innovation defined in the construction industry?

Innovation in the construction industry is usually defined as introducing and adopting new or improved methods, materials, technologies, or ways of working that create real, measurable value in how projects are delivered. That value is typically framed as better efficiency/productivity, cost control, quality, safety, sustainability, or collaboration—not just doing something “new” for its own sake.

In what ways is AI being used within construction?

AI is generally used to improve visibility, reduce risk, and cut manual effort. On sites, it can monitor progress, detect issues early, and support safety through cameras, drones, or sensors. In project management, it helps optimize schedules, budgets, and resource allocation by spotting patterns people might miss. It’s also increasingly used for paperwork-heavy tasks like reviewing drawings, organizing documents, and summarizing updates.

Build Smarter with Claris Design•Build!

Ready to take your next project to the next level with modern, efficient construction techniques?

Claris Design•Build leads the way in commercial construction, delivering innovative methods that cut timelines, lower costs, and support long-term sustainability.

Bring your vision to life with Claris Design•Build. Contact us today!

![[2025 UPDATE] 44 Construction Safety Statistics for 2025](https://www.clarisdesignbuild.com/wp-content/uploads/2024/03/Construction-Safety.jpg)

![[2025 Updates] Top 15 Benefits of AI in the Construction Industry](https://www.clarisdesignbuild.com/wp-content/uploads/2024/03/pexels-pixabay-256090.jpg)